How is advanced.farm modernizing agriculture?

At advanced.farm, we are building robots for the future of farming. As labor shortages disrupt agriculture, robots provide clear advantages for the operation of a farm – they can serve as a reliable supplemental workforce to ensure stable production while reducing expenses. But farming robots’ impact on the average person is equally important. People depend on farms’ reliable outputs of fruits and vegetables for a healthy diet, and farming robots can fortify this supply.

How are specialty crop farms evolving?

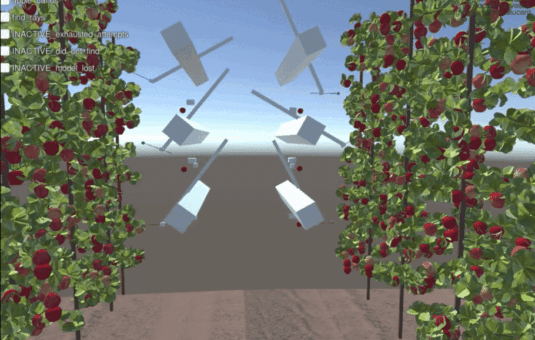

Robotic harvest is a natural extension of recent trends in agriculture. While row crops such as corn and wheat are harvested mechanically, specialty crops such as fresh fruits and vegetables have seen less advancement and are still mostly picked by hand. Farmworkers need to handle these crops with care and pick them promptly once they are visually deemed to be ripe. That said, technology is advancing to use computer vision and robotic arms to select and gently pick fruits. Also, changes to farm layouts are facilitating robotic harvest. For example, the format of apple orchards has shifted from diffuse fruit spread throughout wide trees to “vertical fruiting walls”. This new format increases farmworkers’ efficiency and is conducive to automation – self-driving robots can traverse the rows, and the fruit is accessible to robotic cameras and arms.

While growers increasingly utilize such innovations to improve operational efficiency, the question remains: what is the impact on the end consumer who buys produce at their local farmer’s market or grocery store? To answer this question, we need to look at some current issues in agriculture.

Why do we need farming robots?

Already, labor shortages are imposing a deleterious effect on fresh produce consumers through a lack of supply continuity and rising prices. Of the top 10 most popular fruits and vegetables in the U.S., almost all are currently harvested by hand.

| Fruit | Hand Harvested? |

| #1 Bananas | Yes |

| #2 Apples | Yes |

| #3 Table grapes | Yes |

| #4 Strawberries | Yes |

| #5 Oranges | Yes |

| #6 Watermelon | Yes |

| #7 Lemons | Yes |

| #8 Blueberries | Yes |

| #9 Peaches | Yes |

| #10 Cantaloupe | Yes |

| Vegetable | Hand Harvested? |

| #1 Potatoes | No |

| #2 Tomatoes | Yes |

| #3 Onions | Yes |

| #4 Carrots | No |

| #5 Heads of Lettuce | Yes |

| #6 Broccoli | Yes |

| #7 Mixed salad greens | No |

| #8 Bell peppers | Yes |

| #9 Celery | Yes |

| #10 Cucumbers | Yes |

Reliance on hand picking has several consequences. As labor becomes increasingly scarce in the U.S., some growers are unable to pick all their crops. In fact, a 2019 California Farm Bureau and UC Davis survey of 1,071 farmers and ranchers reported that 56% of respondents were unable to hire enough workers to complete all required tasks on their farms.

Growers’ inability to staff a reliable workforce will inevitably lead to price increases for consumers who already pay premiums for high-quality fruits and vegetables. With obesity at record levels in the United States, access to healthier foods is critical to public health. And even at higher prices, there will be shortages of popular fruits and vegetables if there is insufficient labor to harvest them.

In addition, farms’ entire layout and operational flow centers on human labor, with its associated limitations. Berries are picked by hand and packed immediately into plastic “clamshell” packages, with no opportunity for further sorting or quality grading other than in small samples. Workers could report issues impacting the field such as disease or infestation, but because they are paid “piece rate” by the number of clamshells they harvest, they are incentivized instead to focus on production. Growers instead rely on routine rather than real-time information to maintain their fields. While growers are masterful at what they do, an information gap exists that precludes the deployment of targeted interventions to resolve production issues.

How can farming robots help solve challenges in the grocery store?

Robotic farming can offer relief from these intersecting challenges. Using farming robots to fortify the human workforce, growers can ensure that their fields are thoroughly harvested. Thereby, farming robots will ensure a stable supply of healthy fruits and vegetables for consumers.

In addition, robotic farming has the potential to decrease the agriculture industry’s dependence on pesticides and other chemicals to treat crop diseases and infestations. Advanced monitoring systems, combined with robotic delivery technologies, could enable more targeted application of such chemicals, so they are applied only where there is an active pest issue, not blanketed over the entire growing area. This reduction is desirable for many consumers who increasingly demand minimally processed foods.

Beyond chemical targeting, robotic farming also has the ability to optimize fruit production. By mapping areas of increased or decreased growth, inputs such as water and fertilizer could be deployed with precision, which ultimately could ensure that the entire field receives just the nutrients it needs to ensure an adequate harvest. The associated cost reduction could protect farmers’ ability to stay in business without needing to raise produce prices.

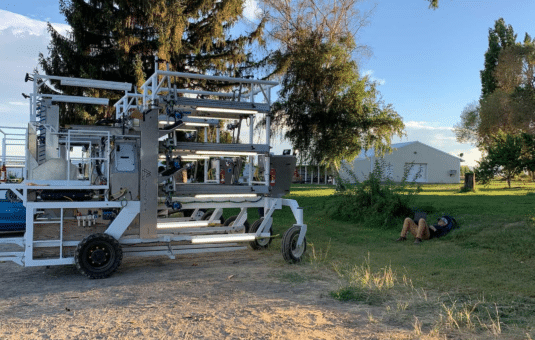

Furthermore, robotic technology will enhance the consumer experience by improving product quality. Right now, quality control must be performed by sampling clamshells to determine that an entire shipment meets standards. advanced.farm is launching a novel system to improve the selectivity of berry packing with our BetterPickTM and BetterPackTM platforms. With these integratable technologies, we are setting a new standard for end-to-end autonomy in fresh fruit harvest. First, our autonomous harvesters pick fruit into bulk bins. The bins of fruit are transported to a nearby cooler, where fruit is then sorted and packed according to customers’ quality criteria before being packed for consumers. With robotic packing and computer vision, each individual berry can be examined prior to packing. This capability will allow producers to better control the quality delivered to consumers, so every berry in a package will be even more enjoyable. Berries with aesthetic defects can be sorted to be used for juice or other applications. Autonomous sorting also has the potential to reduce food waste, since berries not fit for individual snacking will still be used, and fewer shipments of berries will be rejected by retailers.

Finally, society will benefit from new jobs that are created as a result of robotic farming. advanced.farm trains farmworkers to operate and maintain our robotic technology, and in doing so we elevate their career potential and technical skills. We saw a similar phenomenon at Greenbotics, our previous start-up, when we developed robotic solar panel cleaning systems. Robots enabled employees tasked with cleaning panels by hand to become technicians instead, responsible for the performance and maintenance of solar cleaning robots.

As the market leader in robotic farming, advanced.farm is poised to facilitate these improvements for the agriculture industry and society. As we extend our groundbreaking success in strawberry harvesting to farming’s other previously intractable challenges, we will continue to keep the consumer’s best interests at the forefront of our business goals.

Care to see us in action? Schedule a demo today or join our newsletter.

Nathaniel Morrison is a Business Development Intern at advanced.farm and an MBA Candidate at the UC Davis Graduate School of Management. Trained as a chemical engineer at Stanford University, Nathaniel previously worked as a process engineer and a food scientist.

References

- Estabrook, Barry. “Farmers Can’t Find Enough Workers to Harvest Crops—and Fruits and Vegetables Are Literally Rotting in Fields.” EatingWell, https://www.eatingwell.com/article/291645/farmers-cant-find-enough-workers-to-harvest-crops-and-fruits-and-vegetables-are-literally-rotting-in-fields/. Accessed 5 July 2022.

- California Farm Bureau Federation and UC Davis. “Still Searching for Solutions: – Adapting to Farm Worker Scarcity Survey 2019.” California Farm Bureau, 30 April 2019, https://www.cfbf.com/wp-content/uploads/2019/06/LaborScarcity.pdf. Accessed 7 July 2022.