Frequently Asked Questions By Farmers

What does advanced.farm do?

advanced.farm builds robots for the next frontier of farming. Our robots harvest fruit that has traditionally been picked by hand, including strawberries and apples. Our robots also perform other tasks that have traditionally been done all by hand, such as packing strawberries. Our team designs and builds robots in Davis, CA, and has a local presence throughout California and Washington.

How does robotic harvest work?

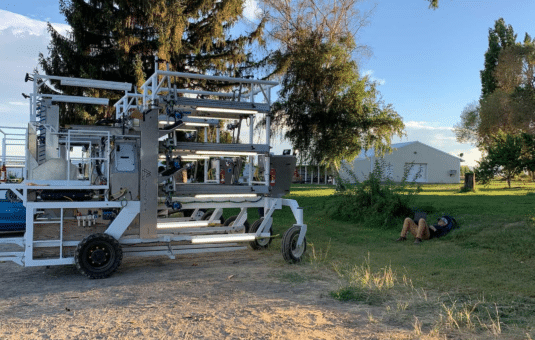

Robotic harvest is made possible through a combination of our patented self-driving lightweight tractor chassis, robust stereo camera, robotic arms, and end-effectors. We have a dedicated field operations team to make integrating our technology on your farm as little of a headache as possible. We work diligently to collaborate with our farming customers by listening to them and integrating with their systems. Our work is a full solution, not just a research project. That is why we have built an automated packline for strawberries to bring innovation to the whole supply chain. See a customer testimonial here.

When will your robots be ready for farmers to use?

Our robotic strawberry harvesters are already being used by companies representing 60% of the strawberry industry in California. Our machines have picked millions of fresh strawberries that have been sold to retail consumers. Many of those berries were picked in the middle of the night when almost no one else was on the farm. Our key metrics are highlighted below; however, we expect these metrics to continue to improve in the future. Read more about how our robots work here.

Key Strawberry Harvest Metrics:

- 100 lbs/hour – pick rate per machine

- 30% headcount reduction during peak season

- 1 worker can operate up to 5 machines at once

- 2 shifts per day – the machines can work day and night

- 6 times more berries picked in 2022 vs. 2021

How do your robots see which fruit is ripe?

Each robotic arm is equipped with a camera that identifies color, size, location, and other attributes that inform our robots’ decisions to pick each piece of fruit. See a video of what our gripper sees.

Do your robots damage the fruit?

No. Our robotic arms and grippers are custom designed to pick fruit gently and quickly. The vast majority of the fruit that we pick is sold into retail as fresh berries. We estimate that our fruit damage is in line with human pickers.

Are farmworkers able to operate your machines?

We designed our machines with farmworkers in mind because they operate the machines in the field. Each machine has easy to use controls (a green button and a red button) and a new user can quickly be trained to use the equipment safely. We intentionally hire bilingual employees to formally train farmworkers to both operate the machines and to perform basic maintenance.

Who services the machine if it breaks down in the field?

advanced.farm takes pride in providing high-quality customer service. In addition to training local farmworkers, we have regional offices near our customers to provide timely mechanical and software support.

Can advanced.farm pick on any ranch or do farmers have to make changes to accommodate them?

advanced.farm does not ask farmers to make changes to their ranch. We recognize that our customers are the experts in farming and that the fruit production system already in place has many benefits. We have also designed our equipment to integrate with existing ranch operations. For example, our apple harvesters are outfitted with bin management systems to be able to pass over bins in the apple rows.

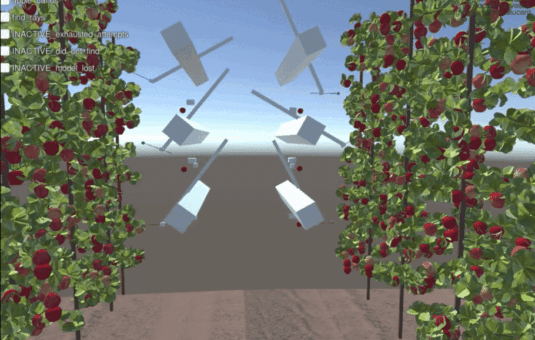

However, certain crop varieties and architectures work better for robotics than others. For example, strawberry varieties with longer stems are less likely to hide berries under their leaves. (Read here about our work to evaluate new strawberry varieties with UC Davis.) In apple orchards, we prefer to pick on vertical fruiting wall trellises. This layout allows the majority of fruit to be identified by our cameras and accessible to our robotic arms. The apple industry has aggressively prepared for automation, and we are thrilled to be working with the Washington Tree Fruit Research Commission.

Can advanced.farm robots be used to pick other fruits and vegetables?

Our technology will be useful in many crops and for many different tasks. Over the course of 3 years, advanced.farm worked diligently to perfect its hardware and software for strawberry picking, building a lot of our technology from the ground up. We have reached a point in which the design of our strawberry harvester is changing very minimally.

We are now repurposing our existing technology to pick other fruits. After our first visit to an apple orchard, we built a robotic apple harvester in just months, using our existing robotic arms, cameras, and codebase. We have also done preliminary testing to show that this technology will be useful in other fruits, such as peaches and plums. We will leverage our core technological platform to fundamentally improve agriculture in many ways and across many crops.

Why did you create a strawberry packline?

As growers transition to automated harvest, we see the need to provide a gentle, efficient method for sorting and packing berries for the end consumer. Our solution (advanced.farm BetterPack) provides growers with an end-to-end, autonomous solution for packing berries that are bulk-harvested in the field. While a grower using our robotic harvester can still opt to sort and pack by hand, BetterPack provides an additional path to reduce harvest cost and headcount in the field. For more information on BetterPack, or to see if your shipper is already offering BetterPack, contact us.

Can I buy a robotic harvester for my farm right now?

advanced.farm leases our machines at a monthly fixed price to farmers. By keeping the capital expenditure low, farmers can see an immediate return on investment. Our leasing model also allows us to continue servicing the equipment regularly. If you would like to lease a machine for your farm, or see a demo, please click here. Or, sign up for our email list to learn more.