Sweet Trays: A new method for bulk harvesting fresh strawberries

Growing up in northern California, my Mom would sometimes stop at a small farm stand after picking me up from school where we would buy fresh strawberries. The taste of a warm freshly picked strawberry mixed with the nostalgia of childhood is a feeling you never forget! At the time, I didn’t think about the huge workforce it takes to produce strawberries.

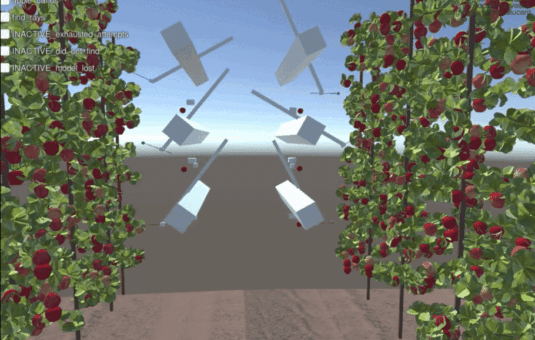

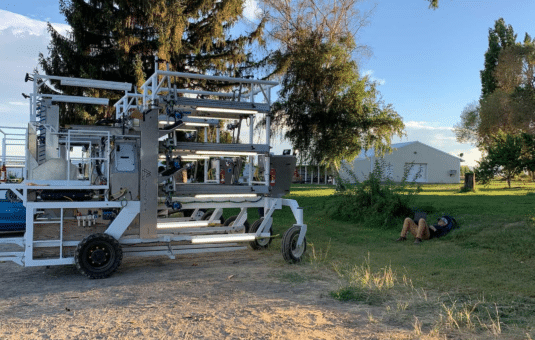

Year round in California, workers sprint through fields, often under the hot sun, picking as many strawberries as they can. Traditionally, these workers will place the strawberries directly into the plastic clamshell container that is then shipped to your local grocery store. As the industry has suffered from a labor shortage, farmers are looking to new solutions. Advanced.farm, an agricultural technology company based in Davis, CA, built an automated packing line for strawberries to help add efficiency to the process. In the new process, workers pick strawberries into a large tray, and then the fruit is sent to the packline where the trays are de-binned by a robot onto a rolling belt and mechanically filled into the plastic clamshells. The pickers in the field are 40% more efficient when picking into the trays compared to the traditional process of simultaneously picking and packing into the plastic clamshells. Customers of the advanced.farm packline are already cutting down on the number of H2A contracts that they need due to the increased field efficiency from this new harvesting method.

The strawberry industry already has trays that are used for harvesting juice fruit. However, this tray proved to have problems for the handling of fresh fruit.

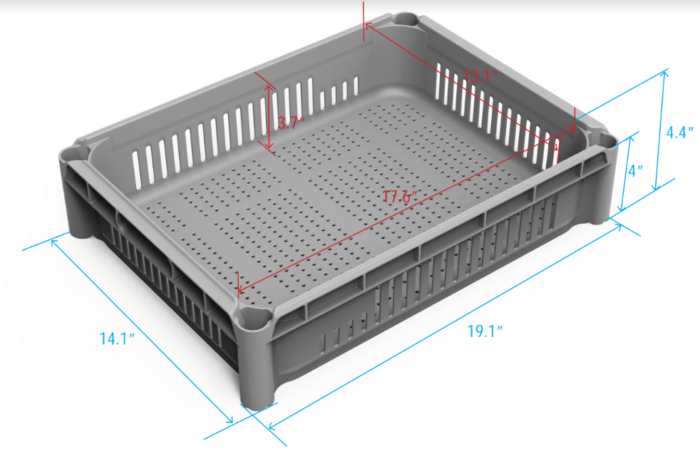

The new tray built by Intercrate, Inc. is called the SweetTray. InterCrate, Inc. is an innovative California corporation that builds containers for the harvesting and distribution of fruits and vegetables. Together, advanced.farm and Intercrate were able to design a tray that had the following characteristics.

- Same footprint as traditional strawberry trays (120 per pallet)

- Holds approximately ten pounds of berries, making it a familiar size for picking crews

- Easily and securely stacks into pallets without risk of falling

- Ventilation and size are ideal for cooling efficiency in the cold room

- Designed for automation; the trays can easily be grasped and dispensed by the robot

- The inside of the tray is smoothed and rounded to prevent fruit damage during transport

Pickers love the speed at which they can harvest using these trays, and growers love the cost savings and reduction in needed labor that come from combining the bulk harvest with the automated packline.

Contact advanced.farm for more information about their automated strawberry packline.

Contact Intercrate for more information about how they can help you with your produce container needs.