How advanced.farm builds robots for new markets

By: Peter Ferguson, Director of Business Development

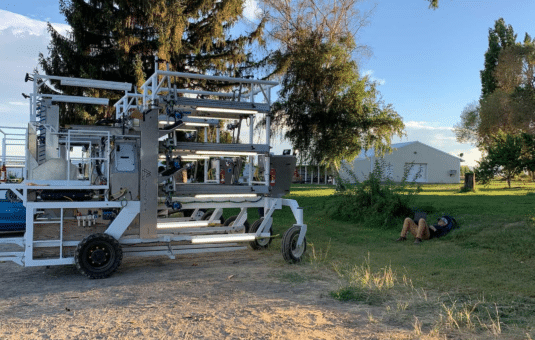

On August 1st, 2022 advanced.farm achieved a major milestone by picking an apple with a robot for the first time. In the following 3 months, our robots picked 80,000 apples. Less than a year earlier, I had landed in Washington for the first time with our CEO, Marc Grossman. We spent 2 days touring central Washington and getting to know various growers in the industry. At the time, we knew almost nothing about apple farming or the layout of an apple orchard. We asked growers about the different kinds of trellises and training systems. We even asked pickers to show us the proper way to hand pick an apple. Given our novice understanding at the time, it was a shock to some of the growers we met on that first trip that we returned less than a year later with 2 fully functioning apple harvesters outfitted with advanced machine vision and robotic arms so that they could autonomously navigate and pick apples. So, how did we make so much progress in such a short amount of time?

Custom Technology Platform

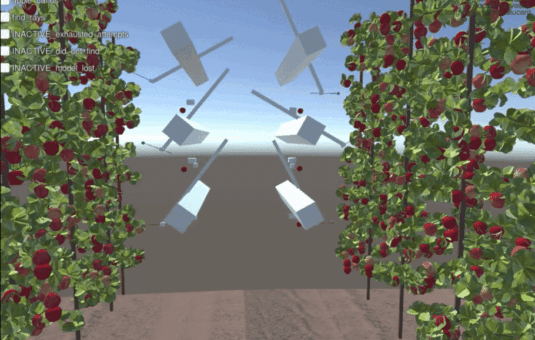

Advanced.farm has been developing autonomous robots to pick strawberries since 2018. As we courted the private markets for investments, a common question from investors was whether or not our technology would be applicable to other crops and farm tasks. As explained in other articles (see here), our tech stack is custom built in house – from the cameras that see the fruit to the arms and grippers that pick the fruit. We used this same technology for our apple harvesters. In fact, many of the systems on our original apple harvester prototype were literally taken straight from one of our previously used strawberry harvesters. Because this tech had several years of iterative development already, its reliability was quite high for a machine that was still in prototype. In addition to apples, we will also use our tech stack to pick stone fruit later this year.

To further define the importance of being able to reuse our technology, it is important to understand our timeline of progress. In strawberries, it took 3 years before our machines achieved a pick rate of 1000 berries/hr. In apples it took only 1 month before achieving a pick rate of 1000 apples/hr. Rather than apples being easier to harvest, this was due to the reuse of proven technology.

As a startup, we must remain laser-focused on the problems we are solving. At this point, we are focused on harvest, specifically for tree-fruit and strawberries. However, we know that in the future the technology platform that we have built will be able to be transferred not only to other crops, but also to other use cases on the farm, like pruning and thinning. We believe in a future where farms have many robots helping them to feed the world.

Product Development Through Business Development

Aside from the purely technological aspect, our success was also driven by our deep commitment to be close to our target customers. I was constantly on the phone and sending texts back and forth with apple farmers. We wanted to make sure we understood everything about apple orchards and apple harvesting. We tried to become experts in the art of tree pruning and the logistics of color picking. We became knowledgeable about different growing systems as well as tree sizing and spacing. In reference to our very frequent trips to Washington from Sacramento, one farmer said to us in our early days of development “it seems like you guys live up here”. We have seen talented ag-tech companies fail as a result of building advanced technology that doesn’t actually do what farmers need it to. While we have expertise in building robots, we rely on our farming partners to inform our product requirements. As we constantly say, the future of farming will be built through the collaboration of innovative technologists and farmers.