When robots help robots: More behind the collaboration between Orchard Robotics and advanced.farm

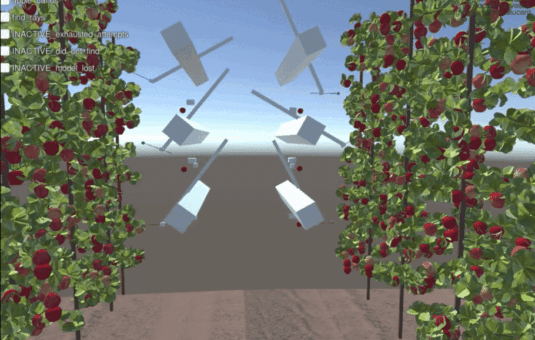

As advanced.farm enters our third season of robotic apple harvesting (on top of 5+ years of strawberry harvesting), we like to think we have a deep understanding of the challenges we’re up against. No – I’ll go a step further – we are deeper into the field of robotic harvesting than any company has ever been. Just a few years ago, we were figuring out how to pick and handle a piece of fruit gently. Now, we are using advanced tooling, ranging from simulation and sophisticated de-bugging tools to cutting-edge algorithms including artificial intelligence and machine learning to shave milliseconds off of our pick rates… but those are topics for another blog post!

Even though we have a deep understanding of how to pick an apple (or strawberry, or peach or plum), there is still some seemingly basic data that is downright hard for us to collect. Counting the amount of fruit on the tree before and after we pick – “thoroughness” in robotics terms – is very tough to measure. Why?

- Field conditions are dynamic: leaves move, branches grow and apples continue to ripen until they’re picked. A count of “ripe apples” on one walk down a row varies wildly from person to person and from day to day. Getting a ground-truth number of how many apples there are at any one time is hard.

- Farm operations move quickly: priorities change during harvest, and often real-time data collection takes a backseat to getting the job done. However, we can’t ignore it because it’s important for us to show the value of robotic harvesting amidst the flurry of activity in the field.

- Robots (and humans) don’t pick all the fruit: Often harvest requires multiple passes to pick only the ripest fruit within a certain color spec. So, when we look at our “thoroughness” it’s not based on the amount of fruit on the tree but instead the amount of ripe fruit on the tree which (for reasons above) is hard to pin down.

As it turns out, we’re not alone – farmers also have a hard time measuring their fruit load. But, for them, it’s less about assessing the efficacy of their robots and more about optimizing their yield and crop load.

One of the leading companies developing a solution in this area – and a company that we’re proud to partner with – is Orchard Robotics.

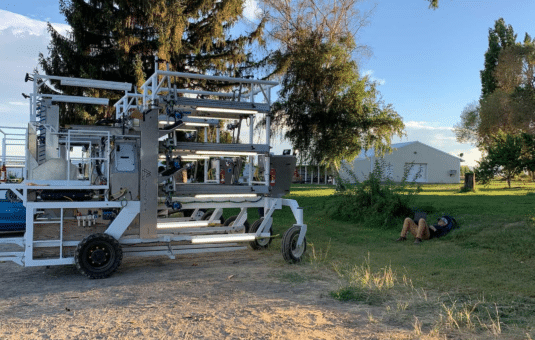

Orchard Robotics was founded by Charlie Wu in 2022 at Cornell University, and is now based in Washington, at the heart of apple country. They help fruit farmers manage their crop with precision, vehicle-mounted, AI-powered camera systems that gather precise data about the fruit on every tree.

Their advanced camera system – about half the size of a shoebox – mounts to any farm vehicle (tractors, ATVs, four-wheelers) in minutes. It takes ~100 images every second of every tree it passes by. Inside the enclosure is a powerful computer running cutting-edge AI & computer vision software to analyze millions of images every day.

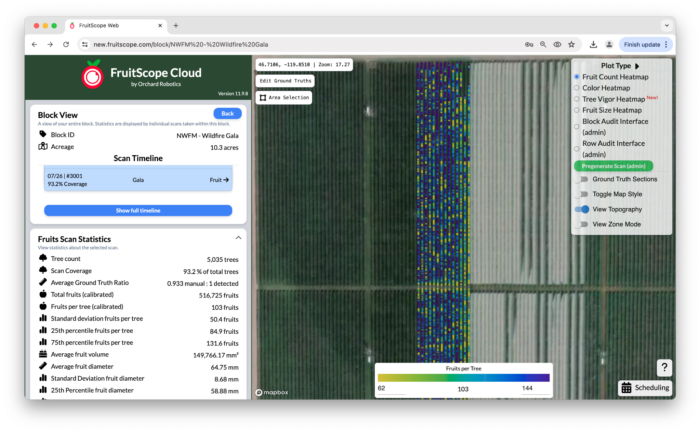

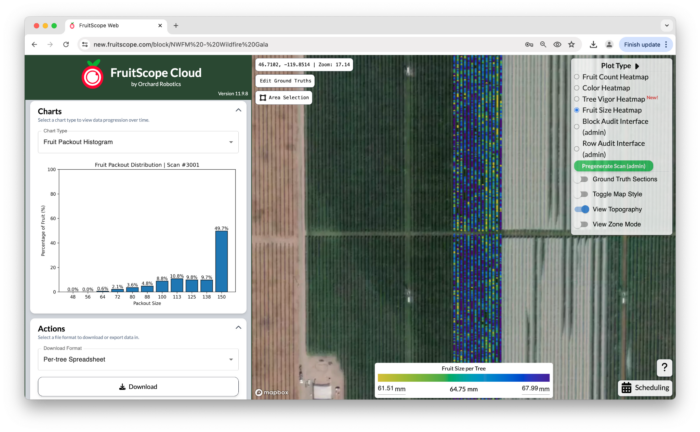

This lets Orchard Robotics deliver precise, tree-specific data to growers throughout the entire season. It begins with accurate counts of dormant buds in the winter, followed by counts of blossoms and fruitlets to inform crop load management. They continue by measuring the count, size, and growth rate of the fruit on each tree through to harvest for reliable yield estimations. The system also captures data on fruit color, tree trunk locations and diameters, canopy areas, and much more.

Their FruitScope software platform enables farmers to integrate this data with their existing operations. Many of our nation’s largest fruit growers already use Orchard Robotics’s technology to maximize crop yield and quality in the field while making strategic supply chain decisions post-harvest.

This is our first year working with Orchard Robotics, but we like what we see. Their data is solid, their UI/UX is beautiful, and their customer service level is something we ourselves aspire to meet. How do we use Orchard Robotics?

Before we arrive to a new ranch, Orchard Robotics scans the blocks that will be harvested by robots. This gives us a detailed distribution of the fruit by row, color and size. We can later use this data and compare it to our own metrics to evaluate how many apples we have picked to give the grower a detailed view of our own performance – and do so in a way that they’re comfortable with.

As we get even deeper into the details of robotic harvest, we love finding partners that can accelerate our progress. We are excited to grow alongside Orchard Robotics as we each scale our solutions in the tree fruit industry.

If you are working in tree fruit, and want to collaborate, we’d love to hear from you! Contact us here.